The Nebraska MEP is continuing a slate of our most popular workshops, focusing on supervisor development, lean practices and process improvement. Each workshop is a one-day session led by experienced manufacturing professionals. The cost is just $250 per participant, including lunch, snacks and all training materials. All workshops are being held at the Nebraska MEP Training & Technology Center, 6200 S. 58th St in Lincoln.

The current schedule:

Job Relations, July 17

examines how to take proper actions and avoid people problems.

Details: https://nemep.unl.edu/job-relations-jr/

Job Instruction, July 24

helps supervisors create uniform instruction processes to perform a job correctly, safely, and conscientiously.

Details: https://nemep.unl.edu/job-instruction-ji/

5S-The Visual Workplace, August 21

helps organize the workplace in a systematic, Lean and efficient way to ensure productivity and safety.

Details: https://nemep.unl.edu/5s-visual-workplace/

Problem Solving, September 18

identifies tools and methods to sharpen problem solving skills.

Details: https://nemep.unl.edu/problem-solving/

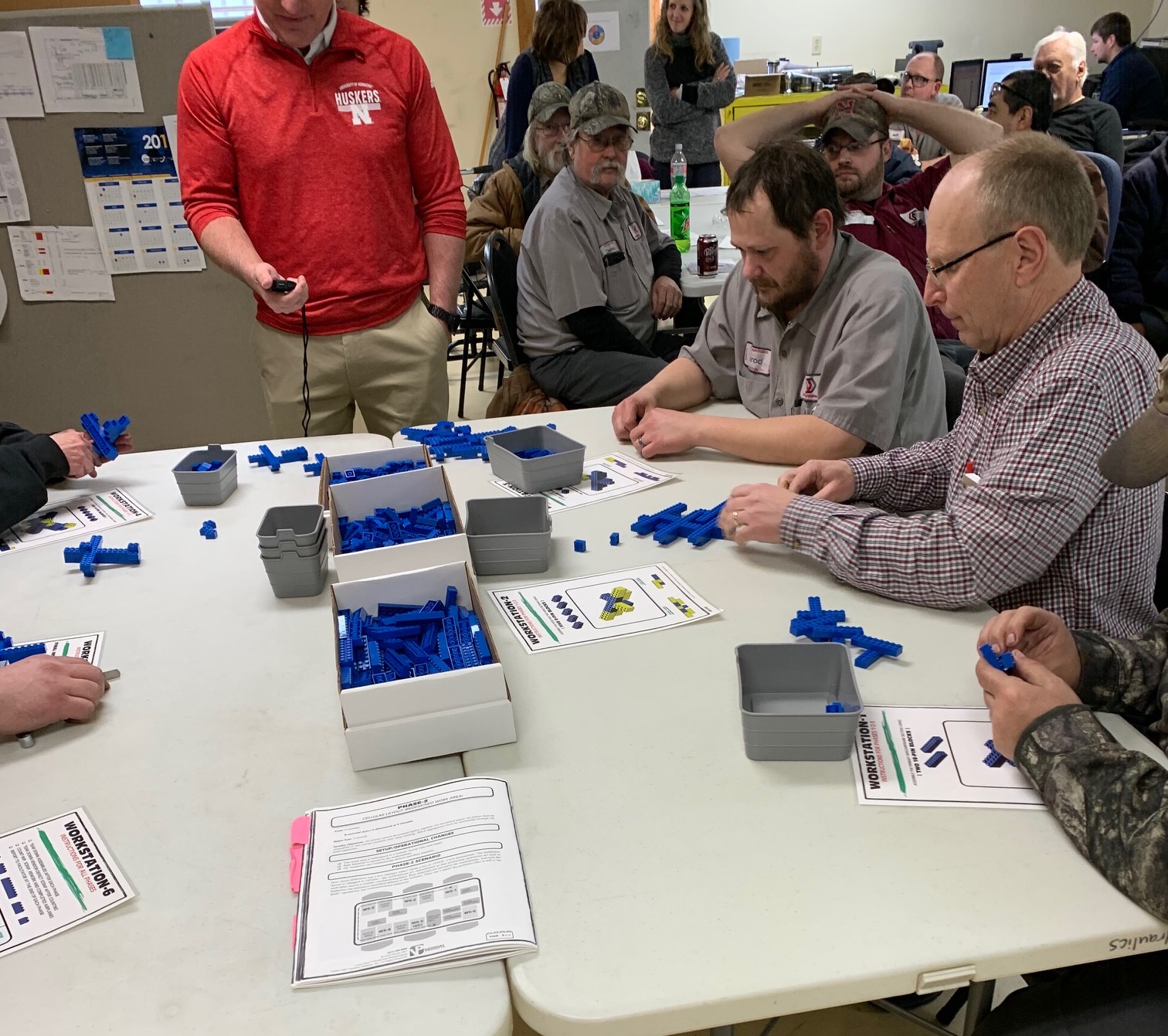

Lean 101 Simulation, October 16

A hands-on simulation class that utilizes lego airplane production to demonstrate Lean methods to improve productivity.

Details: https://nemep.unl.edu/operations-supply-chain/lean-101/

On-site, On-demand

Value Stream Mapping is proven process to discover obstacles and wastes in the production process by diagramming workflows and schedules.

Details: https://nemep.unl.edu/vsm/