Environmental and Water Resources Engineering Seminar Series

April 21, 2023

11:00 AM

404 NH Lincoln

160 PKI Omaha

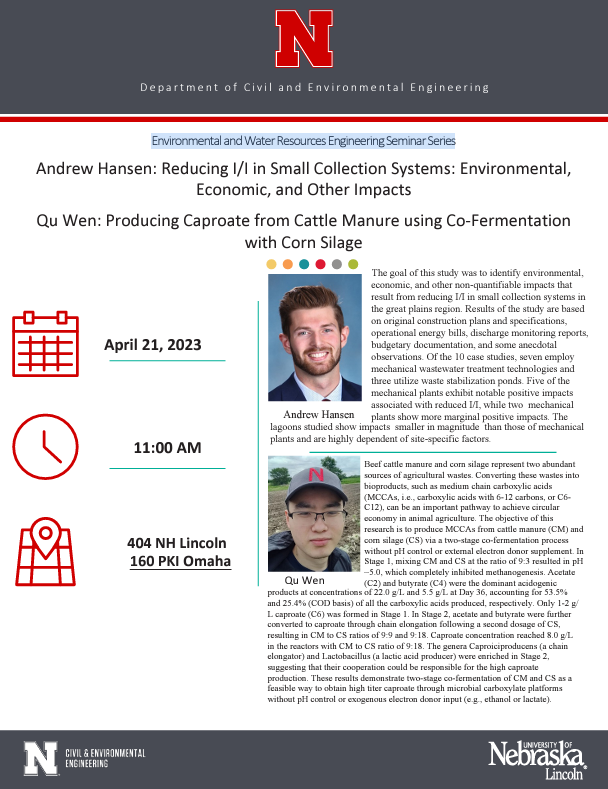

Andrew Hansen: Reducing I/I in Small Collection Systems: Environmental, Economic, and Other Impacts

The goal of this study was to identify environmental, economic, and other non-quantifiable impacts that result from reducing I/I in small collection systems in the great plains region. Results of the study are based on original construction plans and specifications, operational energy bills, discharge monitoring reports, budgetary documentation, and some anecdotal observations. Of the 10 case studies, seven employ mechanical wastewater treatment technologies and three utilize waste stabilization ponds. Five of the mechanical plants exhibit notable positive impacts associated with reduced I/I, while two mechanical plants show more marginal positive impacts. The lagoons studied show impacts smaller in magnitude than those of mechanical plants and are highly dependent of site-specific factors.

Qu Wen: Producing Caproate from Cattle Manure using Co-Fermentation with Corn Silage

Beef cattle manure and corn silage represent two abundant sources of agricultural wastes. Converting these wastes into bioproducts, such as medium chain carboxylic acids (MCCAs, i.e., carboxylic acids with 6-12 carbons, or C6C12), can be an important pathway to achieve circular economy in animal agriculture. The objective of this research is to produce MCCAs from cattle manure (CM) and corn silage (CS) via a two-stage co-fermentation process without pH control or external electron donor supplement. In Stage 1, mixing CM and CS at the ratio of 9:3 resulted in pH ~5.0, which completely inhibited methanogenesis. Acetate (C2) and butyrate (C4) were the dominant acidogenic products at concentrations of 22.0 g/L and 5.5 g/L at Day 36, accounting for 53.5% and 25.4% (COD basis) of all the carboxylic acids produced, respectively. Only 1-2 g/ L caproate (C6) was formed in Stage 1. In Stage 2, acetate and butyrate were further converted to caproate through chain elongation following a second dosage of CS, resulting in CM to CS ratios of 9:9 and 9:18. Caproate concentration reached 8.0 g/L in the reactors with CM to CS ratio of 9:18. The genera Caproiciproducens (a chain elongator) and Lactobacillus (a lactic acid producer) were enriched in Stage 2, suggesting that their cooperation could be responsible for the high caproate production. These results demonstrate two-stage co-fermentation of CM and CS as a feasible way to obtain high titer caproate through microbial carboxylate platforms without pH control or exogenous electron donor input (e.g., ethanol or lactate).