Nine new research projects funded by the Energy Center started on January 1, 2024. NCESR’s overall goal is to foster research and education in energy sciences by providing funding to support innovative research and collaboration among UNL faculty and other public and private-sector organizations and businesses. The principal investigators with the NCESR Cycle 18 seed research grants will present project updates to the NCESR Progress Review Committee on 10/24/2024, which will determine the Cycle 18 projects that will receive Year 2 funding.

Low Cost and Clean Energy Storage Based on Molecular Ferroelectrics and Antiferroelectrics

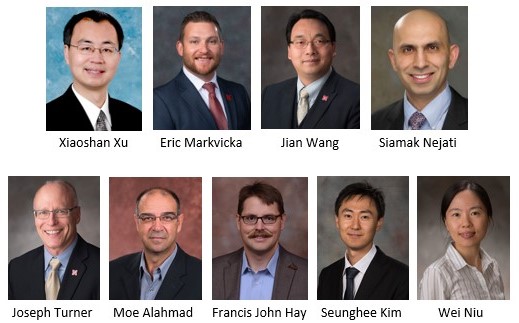

Principal Investigator (PI) – Dr. Xiaoshan Xu, Associate Professor of Physics and Astronomy, College of Arts and Sciences

Co-Principal Investigator (Co-PI) – Dr. Xia Hong, Professor of Physics and Astronomy, College of Arts and Sciences

Co-PI – Dr. Takashi Komesu, Research Associate Professor of Physics and Astronomy, College of Arts and Sciences

This project aims to explore molecular organic thin films for low-cost and clean energy storage with high energy density and high-power density to cope with the fluctuating energy consumption and increase the resilience of energy infrastructure. In the work completed so far, we have managed to control the microstructure of the thin films of molecular ferroelectrics by controlling the growth condition, i.e., the temperature during deposition. Furthermore, we have demonstrated in-situ electrical measurements on the thin films using inter-digital electrodes patterned on the substrates, allowing for real-time monitoring of the electrical properties. These understandings will be critical for optimizing the preparation of organic thin films for capacitor-based energy storage.

Cure-in-Place Phase Change Thermal Interface Material for Superior Thermal Management in High-Power Energy Systems

PI – Dr. Eric Markvicka, Assistant Professor of Mechanical & Materials Engineering, College of Engineering

Co-PI – Dr. Lucia Fernandez-Ballester, Assistant Professor of Mechanical & Materials Engineering, College of Engineering

Our research project aims to address critical heat dissipation challenges in high-power energy systems by developing a soft and tailorable phase change thermal interface material. This material will be engineered to overcome the traditional trade-off between heat storage capacity and thermal conductivity, enabling passive regulation of device temperature while achieving high heat dissipation under significant thermal fluctuations caused by rapid changes in power consumption. During the initial eight months of our research project, our team successfully identified and characterized a family of phase change materials (PCMs) with melting and crystallization temperatures ranging from 40°C to 125°C, which fall within the operational requirements of common microelectronic components. These temperature thresholds are crucial in determining when the PCM absorbs and emits heat, effectively defining its usable temperature range. To address the inherent limitations of conventional PCM materials, we developed a manufacturing process that incorporates the PCM into a room temperature liquid metal (LM), resulting in a multiphase mixture that exhibits both high heat storage capacity and thermal conductivity. We have started to analyze these mixtures using steady-state thermal finite element analysis and characterize their thermal properties using a transient plane source method. Moving forward, our research team will focus on conducting additional experiments in high-power scenarios to evaluate the performance of the PCM and phase change composite and its ability to absorb temperature spikes, ultimately preventing component failure due to thermal runaway.

Discovery of Multiple Element Alloys for Preventing Hydrogen Embrittlement

PI – Dr. Jian Wang, Professor of Mechanical and Materials Engineering, College of Engineering

Co-PI – Dr. Bai Cui, Associate Professor of Mechanical and Materials Engineering, College of Engineering

The degradation of mechanical properties of materials in the presence of hydrogen is known as hydrogen embrittlement (HE). HE failure occurs at low stress levels, causing huge economic losses and even catastrophes. This project focuses on the understanding HE mechanisms of nuclear structural alloys and discovering and designing the chemistries and microstructures of nuclear structural alloys for preventing HE. We have developed methods to characterize hydrogen concentration along grain boundaries and are evaluating the hydrogen effect on the failure of grain boundaries by using in situ micromechanical testing. The methods developed through this project are applicable to other alloys.

Electrocatalysts for Green Hydrogen: Tailored 2D Materials based on Metal Carbide

PI – Dr. Siamak Nejati, Associate Professor of Chemical and Biomolecular Engineering, College of Engineering

Co-PI – Dr. Alexander Sinitskii, Professor of Chemistry, College of Arts and Sciences

In recent years, the push towards greener chemical processes has gained significant momentum, with electrification emerging as a key strategy to reduce emissions. One of the boldest moves has been the growing shift towards utilizing hydrogen as a zero-carbon fuel. Among the various approaches to hydrogen generation, "Green Hydrogen" has taken center stage. Despite the buzz, however, the challenge of achieving cost-effective water splitting and hydrogen production via electrolysis remains substantial. The high energy demand for operating electrolyzers at scale and the associated capital costs present formidable barriers to widespread adoption. While renewable energy holds promise in reducing the carbon footprint of hydrogen production, it’s not enough to solve the problem. A significant portion of the costs lies in the electrolyzer stack itself, particularly in the choice of catalysts. For proton exchange membrane (PEM) electrolyzers, the most established technology, these catalysts rely heavily on critical metals, like iridium oxide, which are both expensive and scarce. In response to this challenge, this project highlights the potential of two-dimensional transition metal carbides, known as MXenes, as effective catalysts in water splitting. Specifically, these materials have shown promise in improving the oxygen evolution reaction (OER), widely recognized as the bottleneck in water splitting. By tuning the chemical composition of MXenes, we are demonstrating that these materials can outperform traditional transition metal oxide catalysts, offering a more sustainable and efficient solution for green hydrogen production.

Next Generation Embedded Wireless Sensors for Structural Health Monitoring of Wind Turbines

PI – Dr. Joseph Turner, Robert W. Brightfelt Professor of Mechanical and Materials Engineering, College of Engineering

Co-PI – Dr. Shubhendu Bhardwaj, Assistant Professor of Electrical and Computer Engineering, College of Engineering

The goal of this project is to design, manufacture, and test a bearing roller that serves as an embedded wireless sensor within a wind turbine gearbox. The initial experiments related to the wireless sensing of temperature change are underway outside of a roller. These experiments will be used to maximize the sensitivity of the measurement for comparison with computational models. Then the sensor design within the roller will be finalized and tested within a load fixture using both mechanical load and heating.

An Intelligent Adaptive Modular Battery Energy Storage System for the Built Environment

PI – Dr. Moe Alahmad, Associate Professor of Durham School of Architectural Engineering and Construction, College of Engineering

Co-PI – Dr. Xiaoqi Liu, Assistant Professor of Durham School of Architectural Engineering and Construction, College of Engineering

Co-PI – Dr. Hamid Sharif, Professor of Electrical and Computer Engineering, College of Engineering

This project aims to develop and demonstrate a framework for integrating Battery Energy Storage Systems (BESS) in buildings. The framework seeks to optimize the design and operation of reconfigurable BESS systems, proposes MEMS sensor technology to improve battery life span and performance, and applies machine learning tools to operate the BESS as a resource for the building, the grid, or both.

We use physics-based models to analyze BESS in multiple scenarios, including cell-level differences in battery health and performance. These models will allow for optimization by utilizing the reconfigurable switching architecture to isolate unhealthy cells or modules and increase the performance and longevity of the BESS.

We’ve developed a cutting-edge model that gives a detailed view of a building’s energy use, breaking it down by category and tracking it in real-time. Our research explores how reinforcement learning—an advanced form of AI—can be applied to manage building energy more efficiently and autonomously. We’ve made the building energy model work with Python-based simulations, making it possible to control energy loads in real-time using AI integrated with the reconfigurable battery system. This innovation could lead to more efficient, self-sustaining buildings.

Microgrid Mastermind: The Quest for Reliable Electricity

PI – Francis John Hay, Extension Educator (Energy) of Biological Systems Engineering, Institute of Agriculture and Natural Resources and College of Engineering

Co-PI – Dr. Jennifer Keshwani, Associate Professor and Extension Specialist of Biological Systems Engineering, Institute of Agriculture and Natural Resources and College of Engineering

The Microgrid Mastermind energy literacy grant team is developing a cooperative classroom game that provides students an opportunity to explore the electric grid. Over the summer of 2024, three student interns developed the first draft of the game. Students took inspiration from three days of tours to NPPD power plants including coal, natural gas, nuclear, and maintenance and control centers. The students designed a 3-D printed game where players build an electric grid to service their city’s load. To win, players must build a grid which is resilient against weather, climate, economic, policy, and wildlife challenges. The game has been played by the advisory team and a few select groups of students. Initial feedback suggests the game is enjoyable and effectively challenges players to think critically about grid generation, loads, transmission, distribution, and reliability. The next step is game piloting with teachers and students, followed by game refinement based on teacher input.

Subsurface Hydrogen Migration and Reactions for Geological Hydrogen Production and Engineered Storage

PI – Dr. Seunghee Kim, Associate Professor of Civil and Environmental Engineering, College of Engineering

Co-PI – Dr. Karrie A. Weber, Director of Microbiology Program, Associate Professor of Earth and Atmospheric Sciences, School of Biological Sciences, College of Arts and Sciences

Co-PI – Dr. Hyun-Seob Song, Associate Professor and Computational Biologist of Biological Systems Engineering, Institute of Agriculture and Natural Resources and College of Engineering

The production of geological hydrogen (H2) and engineered storage of H2 has great potential to alter the horizon of clean energy, long-duration energy storage, and decarbonization. Thus, it is necessary to understand the migration and reaction(s) of H2 with other subsurface fluids, solid minerals, and microorganisms to successfully implement geological H2 production and underground hydrogen storage (UHS). Geologic hydrogen generated near the Midcontinent Rift that runs through Nebraska provides the opportunity for local fuel production and economic development. In this background, the overall objective of this research program is to advance our fundamental understanding of the generation, migration, and reactions of H2 for primary lithological, hydrological, and biogeochemical conditions related to Eastern Nebraska near the Midcontinent Rift.

To achieve this overall goal, there are three research objectives as follows: (1) Examine the diffusive and advective flow of H2 for several key lithological conditions, (2) Examine geologic hydrogen production, with a potential of co-CO2 sequestration, in conjunction with field monitoring at the candidate site near the Midcontinent Rift in NE, and (3) Investigate abiotic/biotic H2 reactions with in-situ fluids and solid minerals, as well as H2 loss/consumption by microorganisms. The research team has been conducting laboratory tests to examine the transport/containment of hydrogen gas under high pressure in the rock samples obtained near the study area for Objective 1. In addition, the research team is nearing the completion of geologic mapping to run field monitoring and sampling in the study area for Objective 2. Lastly, the research team has been conducting a fundamental study to investigate the consumption of natural hydrogen gas through the reaction with solid minerals and microorganisms for Objective 3.

Systems Metabolic Engineering of Pseudomonas Putida for the Bioproduction of C6 Chemicals from Lignin-derived Aromatics

PI – Dr. Wei Niu, Associate Professor of Chemical and Biomolecular Engineering, College of Engineering

Co-PI – Dr. Chi Zhang, Professor of Biochemistry, School of Biological Sciences, College of Arts and Sciences

The gram-negative bacterium Pseudomonas putida KT2440 is emerging as a biotechnological workhorse in bioproduction and bioremediation. The NCESR project focuses on using KT2440 to produce industrially important six-carbon chemicals through systems engineering. The project has enhanced the metabolic traits of KT2440 to utilize syringyl lignin components, which represent 15-30% of the dry weight of lignocellulose and were previously resilient to the native metabolism of wild-type KT2440. Enzyme discovery efforts have also led to the development of new genetically engineered KT2440 with a 30% improvement in the bioproduction of adipic acid, which is primarily used in the production of nylon. This NCESR-supported project is currently also funded by the National Institute of Food and Agriculture (NIFA) of USDA.

NCESR provides major funding for two-year research projects to UNL faculty through collaboration with NPPD. The NCESR funds enable UNL faculty to conduct innovative research to develop or enhance energy science and technologies and educate undergraduate and graduate students on various energy-related aspects. Faculty are expected to use NCESR’s funding as a seed to pursue major external funding. NPPD provides several letters of support for UNL faculty each year as they bid on federal grants (e.g., Department of Energy, Department of Defense, etc.). NCESR also awards annual summer internships for UNL undergraduates to conduct research under the supervision of UNL faculty.