Five new research projects funded by the Energy Center started on January 1, 2025. NCESR’s overall goal is to foster research and education in energy sciences by providing funding to support innovative research and collaboration among UNL faculty and other public and private-sector organizations and businesses. The principal investigators with the NCESR Cycle 19 seed research grants will present project updates to the NCESR Progress Review Committee on October 15, 2025, which will determine the Cycle 19 projects that will receive Year 2 funding.

Project Title: Enhanced CO2 transport for high-efficiency biological carbon capture and biofuel fermentation

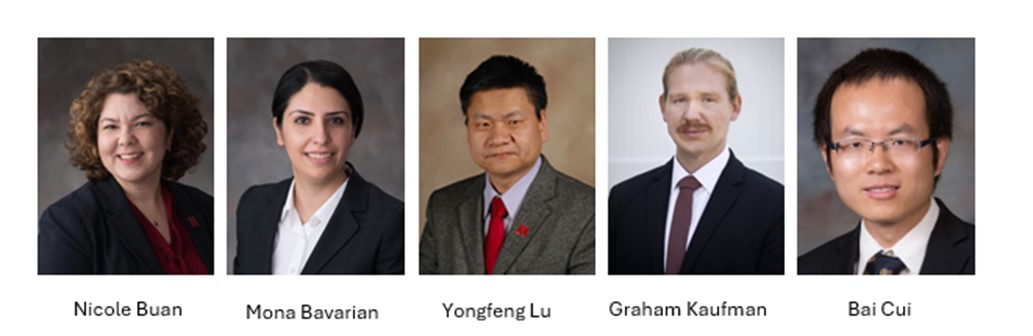

Principal Investigator (PI) – Dr. Nicole Buan, Professor

UNL Department of Biochemistry, Institute of Agriculture and Natural Resources

Co-Principal Investigator (Co-PI) – Dr. Siamak Nejati, Associate Professor

UNL Department of Chemical and Biomolecular Engineering, College of Engineering

Transitioning to a sustainable bioeconomy requires converting up to one billion tons of captured and waste carbon into biofuels each year. Methanosarcina is a promising microbial platform that can be engineered to generate renewable methane and bioisoprene fuels from CO2 and waste carbon at low cost at industrial scale. This project aims to design novel enzymes, bioreactors, and Methanosarcina cells to optimize CO2 conversion selectivity to biogas and bioisoprene, a high-value chemical that can be converted to jet fuel or synthetic rubber. Computational modeling and high-throughput enzyme engineering will be used to design and select for novel enzymes that can be used to enhance carbon capture and biofuels synthesis. Plasmids containing modified enzymes have been synthesized and mutant library validation and screening are in process. Engineered cells and biocatalysts will be embedded into soft materials to design and develop robust gas-liquid contactors for biorefining processes. Methods have been developed to synthesize polyvinylidene fluoride (PVDF) and cellulose triacetate (CTA) nanoparticles <200nm in diameter, which will be used to encapsulate enzymes and whole cell catalysts. If successful, the project's enzymes, materials, and engineered cells are expected to improve carbon capture technologies and enable sustainable biofuel and biomanufacturing in various applications, including for (ethanol) fermentation and biomedical uses. When combined, the novel bioreactors, strains, and enzymes produced have the potential to make a significant impact on converting captured and waste carbon for sustainable aviation and transportation fuel, decarbonizing heavy industry, and reducing greenhouse gas emissions.

Project Title: Innovative Approaches to Sustainable Agriculture: Greening Ammonium Sulfate Production

PI – Dr. Mona Bavarian, Assistant Professor

UNL Department of Chemical and Biomolecular Engineering, College of Engineering

Co-PI – Dr. Yașar Demirel, Professor

UNL Department of Chemical and Biomolecular Engineering, College of Engineering

Co-PI – Dr. Javed Iqbal, Associate Professor

UNL Department of Agronomy and Horticulture, Institute of Agriculture and Natural Resources

Our project, Innovative Approaches to Sustainable Agriculture: Greening Ammonium Sulfate Production, is developing a sustainable pathway to produce ammonium sulfate fertilizer by integrating renewable energy with emission control systems. Leveraging modeling work, we have designed processes where alkaline water electrolyzers generate green hydrogen, which is then fed into a modified Haber–Bosch loop to synthesize green ammonia. This ammonia serves as the reagent in an ammonia-based flue gas desulfurization (FGD) process that captures sulfur dioxide from power plant emissions and converts it into ammonium sulfate fertilizer. During the first reporting period, we achieved significant progress by completing process models for green hydrogen and ammonia production, and initiated detailed modeling of the Efficient Ammonia-Based Desulfurization (EADS) system to target more than 99% SO₂ capture and high ammonia utilization efficiency. By directly linking fertilizer production capacity to Nebraska’s agricultural demand, this approach provides dual benefits: reducing greenhouse gas and sulfur emissions while supplying farmers with a sustainable, locally produced fertilizer. In addition, the project is training graduate and undergraduate students in advanced modeling, techno-economic analysis, and sustainable design, contributing to workforce development in clean energy and agricultural technology.

Project Title: Enhanced Hydrogen Generation and Utilization using Femtosecond Laser-nanostructured NiCo2O4 Electrocatalysts

PI – Dr. Yongfeng Lu, Lott Distinguished University Professor

UNL Department of Electrical Engineering, College of Engineering

Co-PI – Dr. Bai Cui, Professor

UNL Department of Mechanical and Materials Engineering, College of Engineering

Co-PI – Dr. Vitaly Alexandrov, Richard L. McNeel Associate Professor

UNL Department of Chemical and Biomolecular Engineering, College of Engineering

Professors Yongfeng Lu, Bai Cui, and Vitaly Alexandrov have worked on the project entitled "Enhanced Hydrogen Generation and Utilization using Femtosecond Laser-nanostructured NiCo2O4 Electrocatalysts." The project aims to develop efficient bifunctional electrocatalysts for oxygen evolution/reduction reactions (OER/ORR) in unified regenerative fuel cells to advance hydrogen production and utilization. Over the first six months, they have accomplished fabricating laser-induced periodic surface structures (LIPSS) on nickel substrates to enhance electrocatalytic areas, synthesizing NiCo2O4 powders via hydroxide decomposition and fabricating electrodes through electrophoretic deposition, and conducting initial electrochemical characterizations via cyclic voltammetry and DFT simulations to assess doping effects on OER activity. The team has successfully nanostructured Ni substrates, synthesized NiCo2O4 materials, and identified doping strategies for improved performance.

Project Title: Innovative Solutions for Data Center Thermal Management: Oxide-Free Femtosecond Laser Processed Copper Surfaces

PI – Dr. Graham Kaufman, Research Engineer, Research Assistant Professor

UNL Department of Electrical and Computer Engineering, College of Engineering

Co-PI – Dr. Craig Zuhlke, Richard L. McNeel Associate Professor

UNL Department of Electrical and Computer Engineering, College of Engineering

Co-PI – Dr. Jeffrey Shield, Department Chair, Robert W. Brightfelt Professor

UNL Department of Mechanical and Materials Engineering, College of Engineering

The increasing presence of artificial intelligence (AI) in everyday life has brought an immediate need for innovative thermal management solutions in AI computing datacenters. The next generation of thermal management solutions will increase the sustainability of AI datacenters by decreasing the environmental impact associated with cooling AI computing components while simultaneously extending their lifetime. With NCESR’s support, we have developed a highly tunable and scalable surface engineering method that can dissipate the thermal loads generated by AI computing components by using waste heat from the components to boil commercially available engineered fluids that can directly interface with AI server racks. The femtosecond laser-based surface processing technique generates microscale structures that are blanketed in nanoparticles on bulk copper blocks. These features, finer than a human hair, promote boiling and lead to remarkably efficient heat transfer, which will keep computing components cool and prevent the need for the inefficient current thermal management solution of air cooling. Since the beginning of NCESR’s support, we have isolated the role of the laser-generated microscale and nanoscale roughness layers for boiling heat transfer, and devised methods to control each layer independently which has opened doors for us to create optimized boiling surfaces for several different thermal loads.

Project Title: Advanced manufacturing of high-temperature alloy components for small modular reactors

PI – Dr. Bai Cui, Professor

UNL Department of Mechanical and Materials Engineering, College of Engineering

Co-PI – Dr. Yongfeng Lu, Lott Distinguished University Professor

UNL Department of Electrical and Computer Engineering, College of Engineering

Compared to the traditional full-scale nuclear energy plants, small modular reactors (SMRs) have advantages such as smaller physical footprints, reduced capital investment, and the ability to be sited in locations inappropriate for larger nuclear plants. In addition to generating electricity for Nebraskans, SMRs may create new economic opportunities for Nebraska, such as nuclear-powered data Artificial Intelligence data centers and agricultural wastewater treatment plants. This project aims to enable advanced manufacturing of high-temperature alloy components in Nebraska for SMRs. Our team has developed novel additive manufacturing (AM) technologies for advanced austenitic steels, which are structural materials for components of high-temperature SMRs. AM can produce small, high-value components, which have the potential to reduce the deployment time and component fabrication costs of SMRs. Our team has presented our AM technologies at the NSF Workshop on AI-Powered Materials Discovery at Great Plains in June. It will show posters and prototypes of reactor components at the 3rd Nebraska Advanced Nuclear Conference in October 2025. In June 2025, the American Nuclear Society (ANS) board of directors approved to establish the ANS-UNL Student Chapter, in which Alex Rien serves as the President and Dr. Bai Cui serves as the Faculty Advisor.