With an NCESR instrumentation award received by Dr. Lucia Fernandez-Ballester, a unique instrument called flash DSC2+ has been acquired which is capable of measuring the heat released by an extremely small amount of material (down to about 40 ng, that is, 40 billionths of a gram) and which can heat and cool samples at extremely fast rates, up to 40,000 °C/s! With these two new capabilities, the flash DSC2+ provides UNL faculty with exceptional opportunities to study materials critical to energy applications.

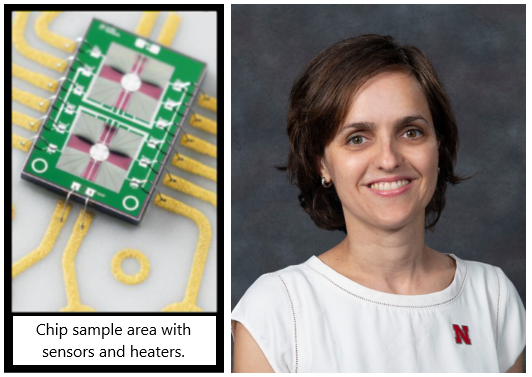

Many electronic and energy devices require the use of very thin films. For example, polymer-based solar cells typically have a 100 nm plastic layer (about 1000 times or so thinner than hair), which absorbs sunlight and converts it into electronic charges. To optimize these thin films, understanding and control are essential to the way they solidify during manufacturing. However, because of the extremely small amount of material in thin films, conventional instruments are not sensitive enough to detect the heat released during solidification (and studying the behavior of large samples is not useful because they behave very differently). To overcome this problem and enable measurements in tiny samples, the flash DSC2+ uses chip-based technology where temperature sensors and heaters are integrated into a small chip, in the center of which a minute sample is placed. This is very different from conventional instruments, where an aluminum pan+lid assembly with the sample is placed on top of a heater, requiring 1,000 times more material than the flash DSC2+!

But measuring phase transitions in tiny samples is not the only outstanding new capability of the flash DSC2+: the small sample size and chip-based technology also enable heating and cooling rates of up to 40,000 °C/s, while only about 0.33 °C/s is possible for conventional instruments! The ability to cool very rapidly opens up the way to create new solid materials with unconventional structures: during solidification at conventional cooling rates, atoms and molecules rapidly arrange themselves into an ordered periodic structure, but if solidification occurs during extremely fast cooling, atoms and molecules become “frozen” in a disordered structure that yields very different properties to the material. In this way, the flash DSC2+ provides researchers a rare chance to obtain and study novel solid materials with potential for energy applications.

Overall, the acquisition of the flash DSC2+ is providing UNL faculty with new, unique capabilities, increasing their competitiveness and enabling access to largely unexplored energy research areas.