We congratulate the six NCESR Cycle 17 projects for focusing on improving renewable and/or sustainable energy. The following Cycle 17 research updates are from the first six months of their funding, which started on January 1, 2023. NCESR provides funding for new two-year seed projects each year through the collaboration with Nebraska Public Power District (NPPD). Cycle 18 proposals are in the review process and awards will be determined at the December 8, 2023 NCESR External Advisory Committee.

Biohydrogen systems for electricity and transportation

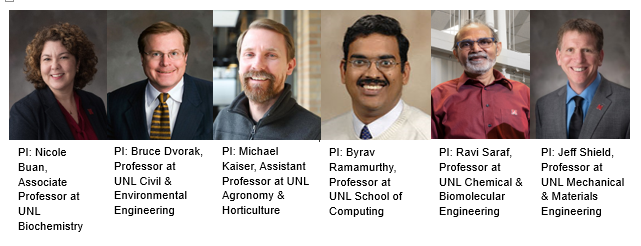

PI: Dr. Nicole Buan, Associate Professor

UNL Biochemistry

Co-PI: Dr. Paul Blum, Professor

UNL School of Biological Sciences

Molecular hydrogen (H2) is a promising clean fuel because of its higher energy content per unit weight (142 kJ g-1 or 61,000 Btu lb-1) relative to alternatives. However, most H2 produced by existing methods is derived from nonrenewable sources such as natural gas and coal that threaten environmental quality. Biological methods for H2 production could provide a renewable H2 source though low productivity has remained an obstacle. However, microbial H2 production using extremophilic organisms has favorable energetics, promotes solubilization and hydrolysis of complex substrates to fermentable sugars, and inhibits the growth of H2 consuming contaminating microorganisms naturally resident in feedstocks.

UNL Professors Nicole Buan and Paul Blum and their team are exploring ways to engineer extremophilic organisms to convert renewable plant-based feedstocks to sustainable “green” H2 fuel. If successful, the team will develop novel microbial strains, demonstrate a bench-scale process and establish a new benchmark for obtaining renewable H2 for the decarbonization of transportation fuel.

Reducing energy to produce corn ethanol by optimizing fermenter operation and off gases treatment

PI: Dr. Bruce Dvorak, Professor

UNL Civil and Environmental Engineering

Co-PI: Dr. Yasar Demirel, Professor

UNL Chemical and Biomolecular Engineering

This project builds on recent studies and ongoing field and lab data collection activities. The overall goal is to illustrate the energy and cost benefits of using the Hazardous Air Pollutant concentrations in the fermenter emissions to optimize air emission treatment. The progress to date includes developing a model of the key ethanol plant processes in ASPEN 14 to simulate real-time plant operation scenarios.

Base models of the drier and fermenter have been finalized using the actual process variables to optimize the plant’s overall heat, energy and water demands. During the summer, two Nebraska ethanol plants were visited to gather operational insights. Fermenter emissions and operating data were collected from one plant for a fermentation cycle to allow for initial processing for modeling using machine learning.

Co-application of biochar and biosolids for carbon sequestration and sustainable soil management in urban-agricultural landscapes.

PI: Dr. Michael Kaiser, Assistant Professor

UNL Agronomy and Horticulture

Co-PI: Dr. Arindam Malakar, Research Assistant Professor

UNL School of Natural Resources/Water Center

Co-PI: Katja Koehler-Cole, Soil Health Management Extension Educator

UNL Nebraska Extension

Sustainable soil management strategies in urban-rural transition zones have the potential to improve soil health, resource efficient food production, and decrease the municipalities’ carbon footprint. Our project will determine the effects of biosolids, an organic fertilizer sourced from urban wastewater treatment, and biochar application to farmland managed with corn-soybean rotations under no-till and cover crops on soil carbon sequestration. It will also determine the retention of nitrate and water in the rooting zone. The field trial was established in April of 2023 and consists of 16 acres of farmland in northeast Lincoln. More than 64 tons of biochar and about 200 tons of biosolids were applied and incorporated using a manure spreader and disc tiller. The size of this experiment - 16 acres/research plots in total, with eight acres/research plots receiving biochar - is among the largest biochar field trials in the United States. The first porewater samples to monitor nitrate leaching were taken during the summer and are currently being analyzed. Soil, grain and biomass samples from the 16 research plots will be collected in September and analyzed until the end of the year.

Smart Grid cybersecurity enhancement using smart authentication and intelligent threat detection

PI: Dr. Byrav Ramamurthy, Professor

UNL School of Computing

Co-PI: Dr. Nirnimesh Ghose, Assistant Professor

UNL School of Computing

This project aims to explore, evaluate and implement smart authentication and traffic analysis techniques to strengthen the security of the Smart Grid cyberinfrastructures. We use innovative Artificial Intelligence (AI) and Machine Learning (ML) based solutions. Two major branches of our approaches are (a) smart authentication of customer premises equipment such as smart meters and (b) real-time traffic analysis to detect anomalous behavior.

We investigated the physical layer device authentication approaches using novel ensemble ML approaches to design a Spatial & Temporal Agnostic Deep-Learning based Radio Fingerprinting method (done by Ph.D. student Fahmida Afrin). We designed and implemented real-time network layer traffic analysis technique using supervised learning for continuous threat detection and identifying potential anomalous network traffic on the smart grid network (done by Ph.D. candidate Venkat Sai Suman). We are combining the former two approaches to design a cross-layer (physical & network layers) framework to secure the end-to-end smart grid networks.

We are building a smart grid testbed in the School of Computing (SoC) to emulate the behavior of smart grid cyberinfrastructures and to help deploy approaches in a sandbox environment. We are also investigating and designing hardware-security-based strategies to protect the customer and the provider equipment from cyber-attacks. Finally, we are exploring the adversarial AI/ML approaches to make device identification by a malicious attacker more complex, thus protecting the device discovery by unknown parties.

Photocatalytic Corrosive Nanostructured Electrode to Split Water

PI: Dr. Ravi Saraf, Professor

UNL Chemical and Biomolecular Engineering

Co-PI: Dr. Laura Wang, Assistant Professor

UNL Electrical and Computer Engineering

Using solar energy to split water and harvest hydrogen is a promising strategy to build a sustainable society with zero-carbon emissions for energy production and storage. However, in the photocatalyst methods based on pure semiconductors, only UV light, which is ~2% of the solar spectrum, could be utilized to overcome the energy/potential barriers for water splitting.

Recently, systems of metal plasmonic structures interfaced with semiconductors have been proposed as a promising approach that leverages ~47% of the solar spectrum. This collaborative NCESR Cycle 17 Project led by Saraf and Wang focuses on developing a nanoparticle necklace network (N3) engineered by nano-cementing 10 nm gold (Au) particles with semiconductors to form a monolayer of one-dimensional (1D) chains. The small inter-particle gap in N3 enhances the electric field intensity by 150-fold compared to individual nanoparticles. Owing to the delocalization of the electrons in the nanoparticle chains, the absorption spectrum is broadened from the wavelength range of 420-600 nm for a single particle to 420-800 nm for N3, covering the whole visible solar spectrum range.

The nanoscale size of N3 with semiconducting nano-cement at multiple junctions between each particle has a highly significant catalytic effect at large surface-to-volume ratio. As a result, for the electro-catalytic splitting of water, the hydrogen adsorption on reactive sites of N3 is enhanced by at least 2-fold, leading to a more than 50% increase in electrochemical current for hydrogen gas production, compared to a planar Au electrode.

Additive Manufacturing of Advanced Magnets for Power Systems ((AM)2PS)

PI: Dr. Jeff Shield, Professor

UNL Mechanical and Materials Engineering

Co-PI: Dr. Qilin Guo, Associate Professor

UNL Mechanical and Materials Engineering

This work is focused on developing alloy compositions amenable to additive manufacturing (AM, a.k.a. 3D printing) of rare earth permanent magnets and then establishing AM processing windows to produce magnets. AM provides unparalleled design flexibility and reduces material usage. In this project, we are using melt spinning as a rapid throughput analogous processing scheme. We have developed an alloy with a much more uniform microstructure under AM-like solidification conditions. We have created powder from these alloys, and have established processing parameters to produce fully dense parts built by laser powder bed fusion, a common AM process. The laser power, scan speed, and hatch spacing all affect the build process, while x-ray computed tomography (XCT) provides information on the internal structure, notably porosity. We are also partnering with Hoeganaes, a powder supplier, printing some of its recently developed rare earth magnet alloy powder. Our work is being presented at REPM2023, a biennial conference on high-energy permanent magnet research which brings together industry and academic researchers, in September, as well as the TMS Annual Conference in March 2024.